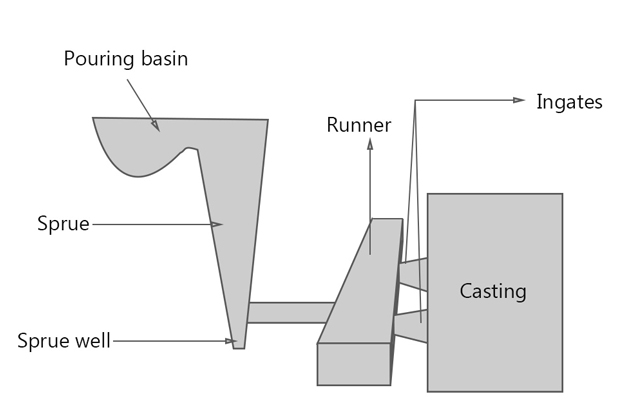

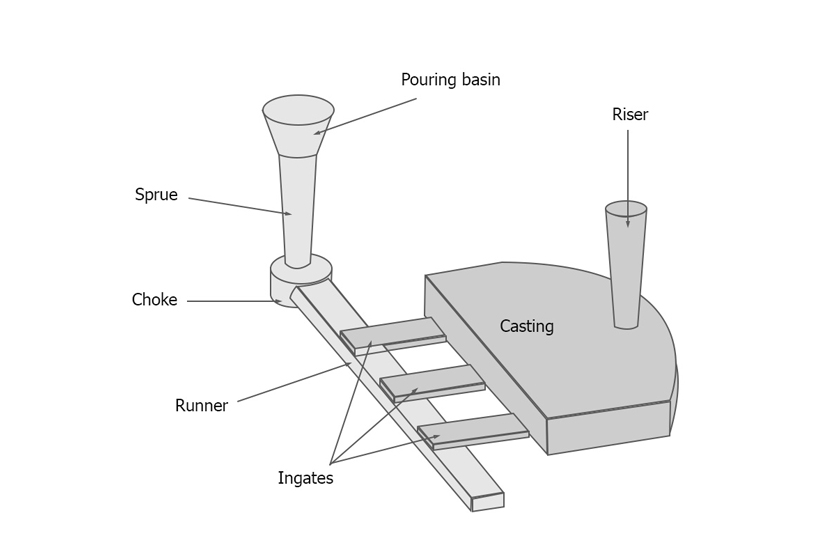

Increasing the metallostatic pressure by a gating system modification can improve the feeding ability of the solidifying metal. The riser and gating system in casting process is shown in Figure 8.

Gating System For Casting Excellent Animation Youtube

Pouring time- The time for complete filling of mould termed as pouring time.

. Iv CONTENTS What Has been So Far. For steel casting Pouring time t 24335 - 03953 log ww sec. Pouring bushbasin for larger casting 2.

There are several objectives to efficient gating design. Up to 24 cash back Casting Mold and Gating System Design Directional Solidification and Troubleshooting In the previous sections we discussed the fundamental aspects of manufacturing parts by metal casting. If the liquid metal is poured very slowly then the time taken to fill up the mould is rather.

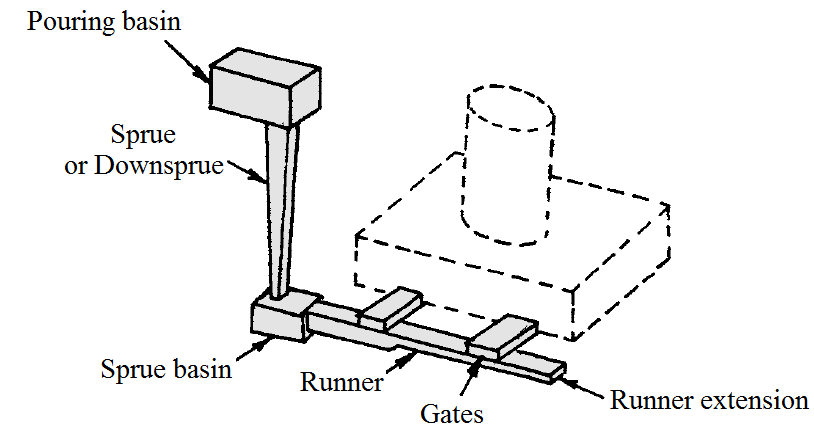

Riser for sand casting process 361 Design Requirements of Risers 1. An offset pouring basin with a step before the sprue entrance a nozzle extension submerged into the pouring basin and a whirl gate1819 A model for predicting the entrained air during mold filling allows casting process engineers to evaluate pouring con-ditions and gating systems. Gating Design The gating system is that part of the mold cavity through which the metal is poured to fill the casting impression.

Such a gating system is applied to increase the yield. Challenge in die casting is design and manufacturing of die. Length of Runner should be 30-50 mm greater than the actual casting So.

Also we discussed the casting operation itself including the pouring. Gating System Design Optimization for Sand Casting Dolar Vaghasia 07310032. The runner alone is given a larger cross-sectional area to reduce the velocity and to aid.

Which provides an opportunity to shape the gating system closely to the theoretically ideal model. Cross-Sectional area of a Gate 6252 cm 2. We covered the creation of patterns and the setup of the mold and gating system.

In the previous lecture we have seen the gating system the meaning of the Gating System. This article discusses various desirable design considerations for the gating system. Compared with the initial design it is found that the optimized casting design can decrease porosity around.

The side riser is a live riser receiving the last hot metal to enter the mold. We have seen that Gating System refers to all the sections. Bottom feeding investment castings reduced the oxide films presence to a minimum and shrinkage by 90 and hence improved the reliability when compared to top filling.

- the free height of the metal in the runner and gate area. Gating ratio for a pressurized gating system. Karunakar Department of Mechanical and Industrial Engineering Indian Institute of Technology Roorkee Module 02 Sand Casting Process Lecture 15 Design Of Gating System-II Welcome back friends.

Integration of design and analysis yields to better results. The importance of gating technique arises from its fourfold purpose 1. 1 Department of Mechanical Engineering Lagos State University Epe.

Directional solidification in order to achieve sound casting. The casting manufacturing design concepts encompass an extensive body of knowledge enshrined in Campbell s Ten. H Length of Runner Gate.

The rate of flow of molten metal through the gates depend on. Where Q metal flow rate mm. Short-length connections are most desirable.

V metal velocity in runner mms g acceleration due to gravity mms. For such single heavy castings failure is unthinkably costly so that any additional help to ensure success is always welcome Ref 9-14. The team discussed factors that need to be considered in developing a naturally pressurized gating system.

Another major element is filter or slag trap which usually placed in runner or between runner and ingate to filter slag and other inclusions. Xxxiii Prologue For This Book xxxvii Version 01 January 12 2009. In the thesis one engine block is used to verify the effectiveness of the optimization method.

23 Determinedecide on total filling time of casting. Risers and Riser Design Riser must be separated from the casting upon completion so the connection area must be as small as possible Figure 11-13 Schematic of a sand casting mold showing a an open-type top riser and b a blind-type side riser. Unlike in traditional investment casting rigging where it has a center tree sprue.

3 Gating Design Difficulties faced in pouring and explain how these can be overcome by using an appropriate gating design A good gating system ensures distribution of the metal in the mould cavity at a proper rate without excessive temperature loss turbulence and entrapping gases and slags. An investment casting but not truly a naturally pressurized gating design for investment castings. Defects may arise in the casting that are direct results of poor gating practices implemented by blindly following gating guidelines.

Gating system features significantly reduces air entrain-ment. - the velocity with which metal is flowing in the runner. S b gate width mm.

Its design is the principal means by which the foundry man can control the pattern of metal flow within the mold. 26 Full PDFs related to this paper. Gating System Design Solutions for Casting De fects from Pouring.

2012investigated on conventional gating design casting defects such as shrinkage and gas porosities were found in front axle housing a critical automotive component. By gaining a better understanding of these methods and practices improvements in casting yields and integrity should be realized. Gatingriser system design is optimized to improve casting quality.

Where w mass of the casting kg. Full PDF Package Download Full PDF Package. See Appendix 1 and Appendix 2.

A short summary of this paper. A gating system is the conduit network through which liquid metal enters a mold and flows to fill the mold cavity where the metal can then solidify to form the desired casting shape. Cross-Sectional area of a runner 4168 cm 2.

Gating System Design Optimization for Sand Casting Dolar Vaghasia 07310032. DESIGN OF DOWN-RUNNER OR SPRUE 21 Calculate the weight of liquid metal to be poured includes the casting the feeder and all elements of gating system 22 Choose location and design of gating system. 24 Gating design Calculations.

Up to 10 cash back 3. On having a closer look this is a partially pressurized system.

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Pdf Gating Design Criteria For Sound Casting Semantic Scholar

Pdf Automation Of Gating System Parameters For Green Sand Iron Castings

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Types Of Gating System In Casting Process Bajrang Engineering

Pdf Optimized Design Of Gating Riser System In Casting Based On Cad And Simulation Technology Semantic Scholar

Types Of Gating System In Casting Process Bajrang Engineering

0 comments

Post a Comment