Primary sludge When raw sewage is settled in a primary clarifier the suspended solids settle down by gravity. From WEF 2005 Clarifier Design Manual of Practice No.

Clarifier Basics How Do Clarifiers Work I Clarifier Design Youtube

Design calculations for an activated sludge aeration tank and a discussion of activated sludge operational calculations.

. In reality 60 removal is assumed not designed for. The entrance of the clarifier where water comes from the flocculator is the source of the flow. Determine the size of the clarifier that will thicken the solids to 10000 mgL.

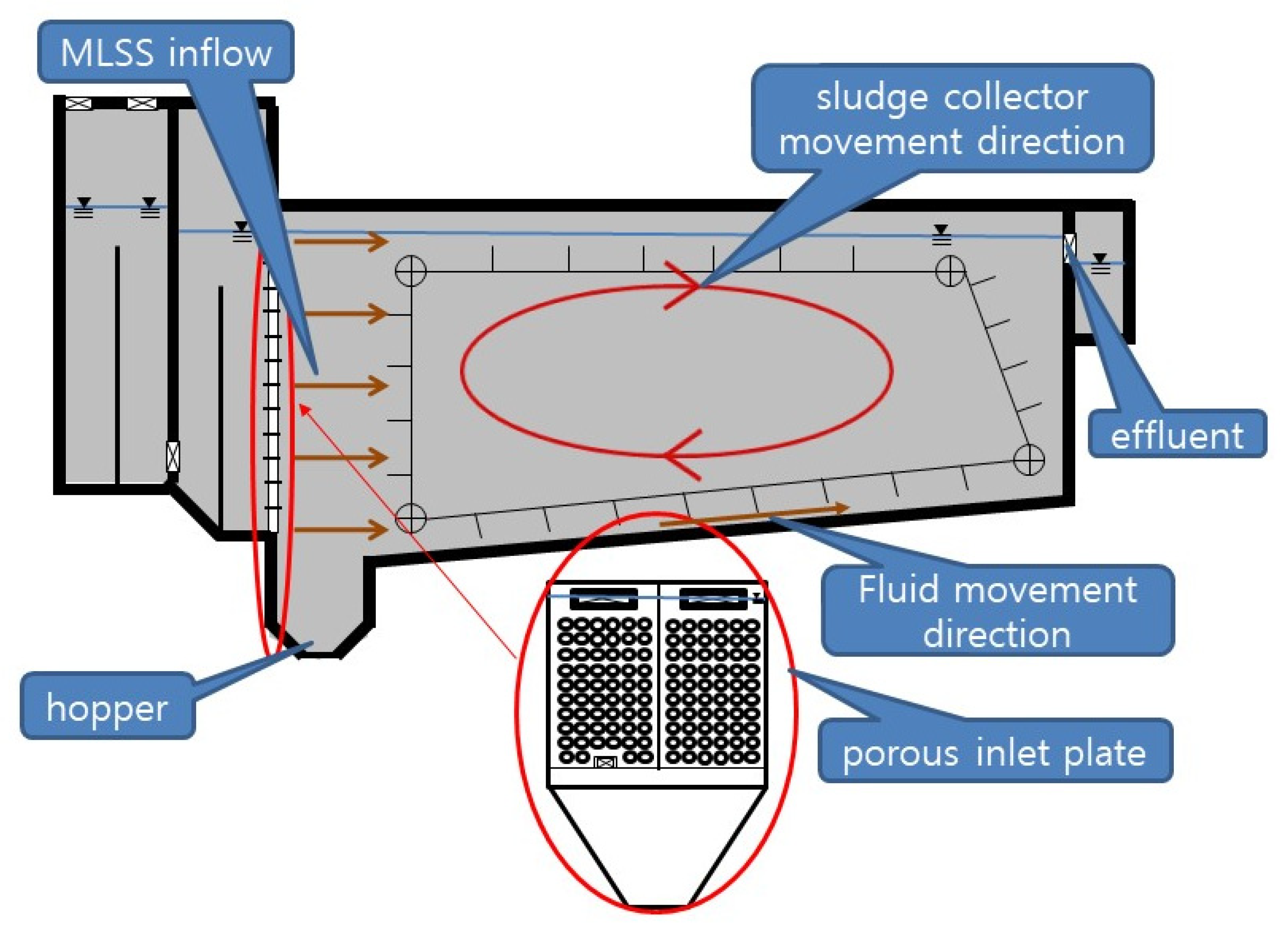

The clarifiers are used in water and wastewater treatment process to remove suspended solids from water under the sole influence of gravity. The velocity between bars 3. For exampleas shown in Figure 4a decrease in RAS solids concentration Xras from 8000 to 7000 mgLdue to decrease in.

FEDWA flocculating energy dissipating feedwell LA - EDI Impinging outlets Lower feed elevation Feed discharge vertically without restriction. Poor clarifier design and operation. This tool is useful in determining the dimensions of a rectangular clarifier.

A 100 mL sample of wastewater influent is found to have an initial DO reading of 78 mgL and a final DO reading of 32 mgL. Floatable solids include objects and debris that are positively buoyant meaning they float. 5 CHAPTER 5 Clarifiers 51 General Criteria 511 Purpose 512 Number of Units 513 Arrangements 514 Tank Configurations 515 Flow Distribution 52 Design Loading 521 Primary Clarifiers 522 Intermediate Clarifiers 523 Final Clarifiers 524 Weir Loading Rates 525 DepthDetention Time.

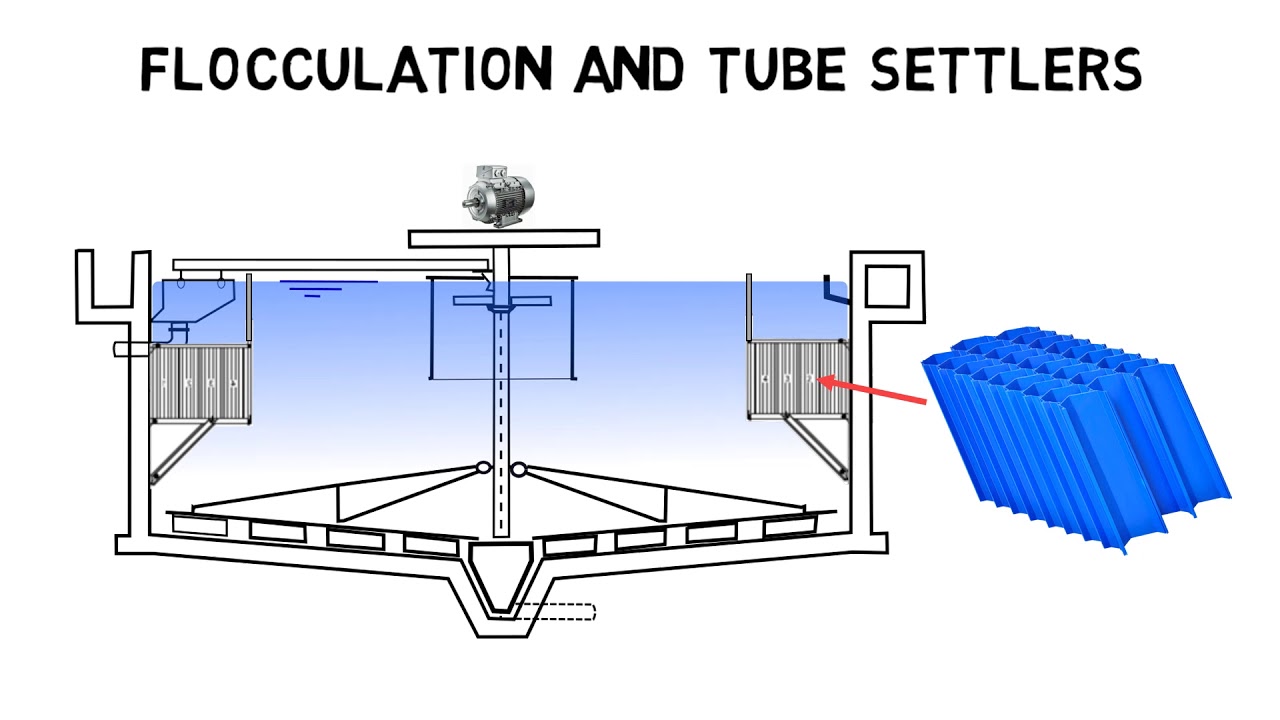

The unique design of the Monroe 3-axis pivoting scum wiper blade ensures constant contact with the scum beach providing the highest scum removal efficiency possible. The angles and configurations of the plates are vastly different from manufacturer to manufacturer. We have noticed an unusual activity from your IP 2074613199 and blocked access to this website.

The objective of the primary clarifier chapter in WEFs new Clarifier Manual of Practice is to move away from empiricism and towards something more rational and at the same time practical. Primary clarifiers are very effective at removing floatable and settleable solids from the wastewater flow stream so the answer is A settleable and floatable. In the course the reader will find guidance of how to select the most appropriate configuration surface overflow rate hydraulic detention time and depth of.

Where to Find Activated Sludge Secondary Clarifier Design Spreadsheets. Primary Clarifier Design Calculation. MLSS concentration as shown below.

6 These design parameters may change slightly based on site-specific conditions. The sample needs a correction factor of 069 mgL. Read on for information about the use of an Excel spreadsheet.

D Suspended and organic. But other design variables are all over the map. 8 9 Primary and secondary clarifiers essentially share the same primary function.

The primary clarifier is used to remove settleable suspended. G MLSS kgm 3. These are drawn out from the conical floor of the clarifier.

For an Excel spreadsheet for activated sludge secondary clarifier design calculations click here to visit our spreadsheet store. Diameter 115 ft SWD 1333 ft Feedwell dia 23 ft Feedwell depth 115 ft Tested at SLR of 373 ppdft2. Overall clarifier volume from the largest to the smallest designs can fluctuate as much as 150 or more.

Example calculations and sample Excel spreadsheets for making the calculations are also included. The more particles there are within design the better the settling. This Excel spreadsheet can handle primary and secondary clarifier surface area calculations and determine diameter for circular clarifier s or length and width for rectangular clarifier s and is available in either US.

Learning Objectives At the conclusion of this course. January 2016 5-1 Design Criteria Ch. Overall the adoption of primary clarification units represents fewer problems on the downstream biological process operation.

37 Full PDFs related to this paper. Full PDF Package Download Full PDF Package. The head loss in meters 4.

Typical design parameters for primary clarifiers in municipal treatment Conditions Affecting Settling Factors. The cross section of the channel and the dimension needed 2. They also have similar configurations and designs.

For example it is not uncommon to see in many wastewater treatment plant master or facilities plans a statement such as The primary clarifiers are designed to remove 60 of the total suspended solids Never is any basis given for such statements. Plot solids flux vs. For example there will be a lower quantity of oil and grease and biomass accumulation in the biological reactor minimizing possible settlements in the tank and reducing the tendency to non filamentous.

In meeting this objective emphasis is placed on understanding primary clarifier performance focusing on the process objective of primary clarifiers and factors affecting their performance. Velocity mh Results of the Solid Flux. The AguaClara treatment train is designed so that flow is driven by potential energy.

We will 7 examine these parameters in greater detail later in the chapter. It will have mostly organic substances and also inorganic substances. Proper dimensions and positioning of the baffle prevents carryover.

Concentration of Solids- The larger and heavier the suspended solids the faster they will settle. Using the given information determine the BOD for the influent in mgL. Bar Screen Design Example A manual bar screen is to be used in an approach channel with a maximum velocity of 064 ms and a design flow of 300 Ls.

B Floatable and dissolved. C Dissolved and colloidal. Plate spacing will vary from 34 to 2 and more.

A short summary of this paper. The bars are 10 mm thick and openings are 3 cm wide. Please confirm that you are not a robot.

Calculate the solids flux from the above data. Units at a very low cost only 1195 in our spreadsheet store. Obtain a convenient easy to use primary and secondary clarifier design spreadsheets for only 1195.

Clarifier Effluent A scum baffle prevents floating matter from reaching the effluent launder. To remove 10 solids from water using sedimentation. This is called primary sludge PS.

This article outlines factors that are cen-tral to the design and operation ofclarifiers as well as tools available to analyze and pre-. In our clarifier as a circuit concept we will draw parallels between how electrons flow through a circuit to how water flows through the clarifier.

Design Of Wastewater Treatment Plant Clarifiersedimentation Tank Design

Schematic Overview Of The Process Layout Of The Zele Wastewater Download Scientific Diagram

2 Cross Section Through A Typical Radial Flow Final Clarifier Adapted Download Scientific Diagram

State Point Analysis Clarifier Design Rules Youtube

Water Free Full Text Comparison Of Effluent Suspended Solid Concentrations From Two Types Of Rectangular Secondary Clarifiers Html

Schematic Illustration Of A Clarifier As Usually Employed After A Download Scientific Diagram

0 comments

Post a Comment